Our factory uses real-time data analysis, artificial intelligence (AI), and machine learning in the manufacturing process to realize intelligent manufacturing. The self-developed automated plant improves production efficiency and cost reduction.

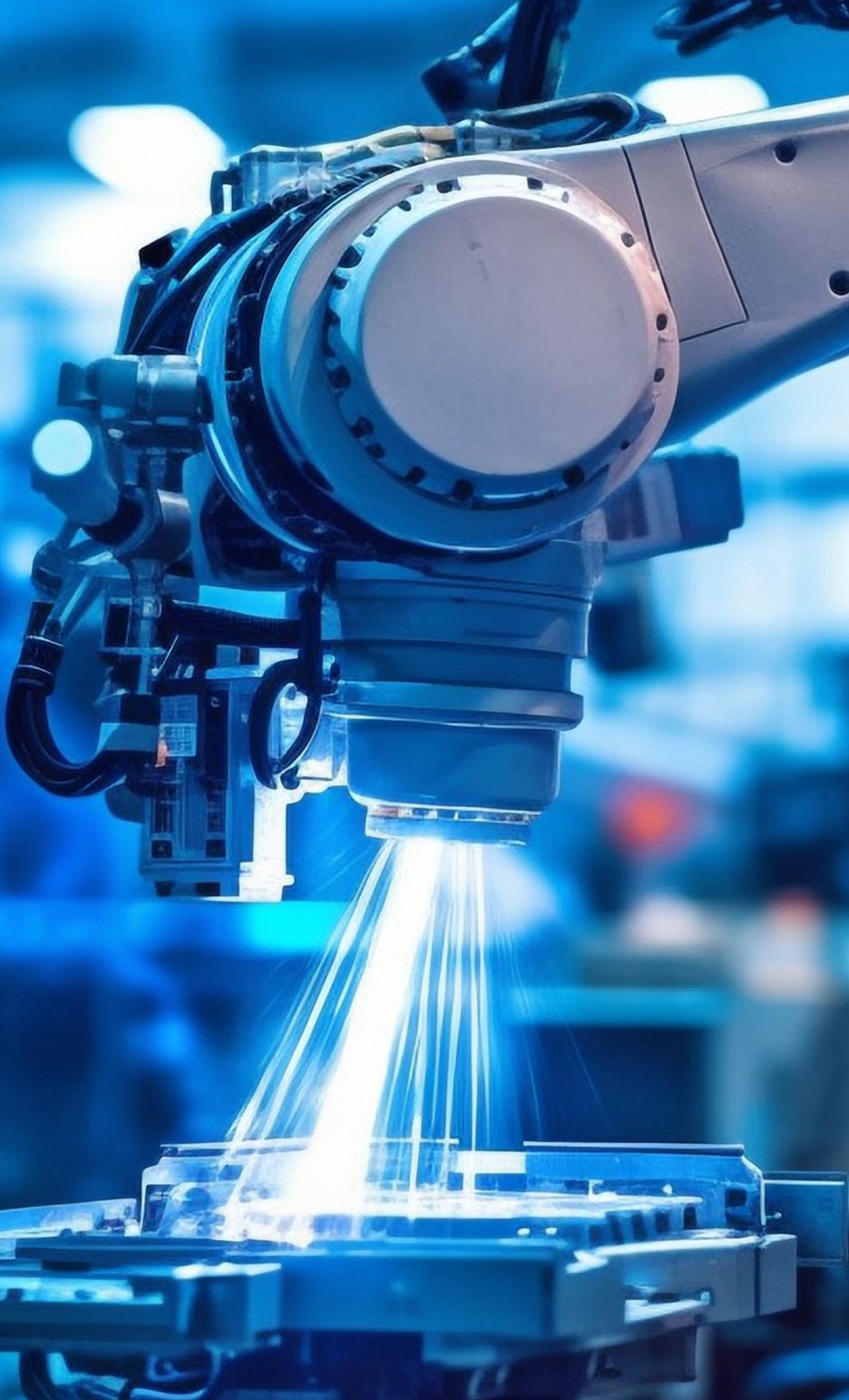

The state-of-the-art vape automated production line has encompassed a comprehensive range of processes, which include bracket and silicone assembly, welding heating wire, oil guide cotton inspection, automated e-liquid filling, and functional testing.

Pioneer in Automatic Robots

The automatic robot arms are wholly invented and developed by our team, which is unique in this field. They supports both disposable products and POD systems, enabling a diverse range of vaping products. This compatibility allows SMOANT to cater to various customer preferences while maintaining vape manufacturing solutions.

Embracing smart manufacturing principles, the automated plant can reduce labour requirements and save time, cost and waste.

In contrast to traditional manual assembly methods, SMOANT’s smart vape manufacturing process approach significantly reduces labor costs while improving production efficiency by more than 50%.

Automated production enable us to be alerted to problems or errors that need to be addressed. By collecting and analysing data, we will be able to review the health of our production lines. Once the problems identified, we can make appropriate adjustments, and even prevent problems before they occur, reducing the risk of poor quality products, downtime or disruption. In this way, we can better ensure that every SMOANT product is of the highest standard.

AGE VERIFICATION

To use the Smoant Website you must be aged 21 years or over. Please verify your age before entering the site. We use cookies to improve our website and your experience browsing. By continuing to browse our website, you accept our cookie policy